Table of Contents:

Why Maintenance Management Matters

Reactive vs Preventive Maintenance

The Power of Automation in Maintenance Management: Streamlining and Strategic Focus

Enhancing Accountability, Cost Efficiency, and Reducing Downtime

Data-Driven Insights in Automated Maintenance Management

Strategic Advancement through Long-Term Data Analysis

Embracing Technology: The Evolving Business Mindset

Looking Ahead: Maintenance Management in 2024 and Beyond

Streamlining Operations with Automated Maintenance Management: A Game-Changer for Businesses

As any business leader will testify, efficiency is more than just a buzzword – it’s a crucial component of smooth operations across all organizations and sectors. At the forefront of this is automated maintenance management, rapidly becoming an essential tool for streamlining workflows and ensuring compliance. Maintenance management is all about ensuring that your tools, facilities, and various assets are not only in top condition and safe but also readily available when needed. Yet, the traditional manual maintenance management often proves to be cumbersome and prone to error. Herein lies the transformative power of automation through software tools.

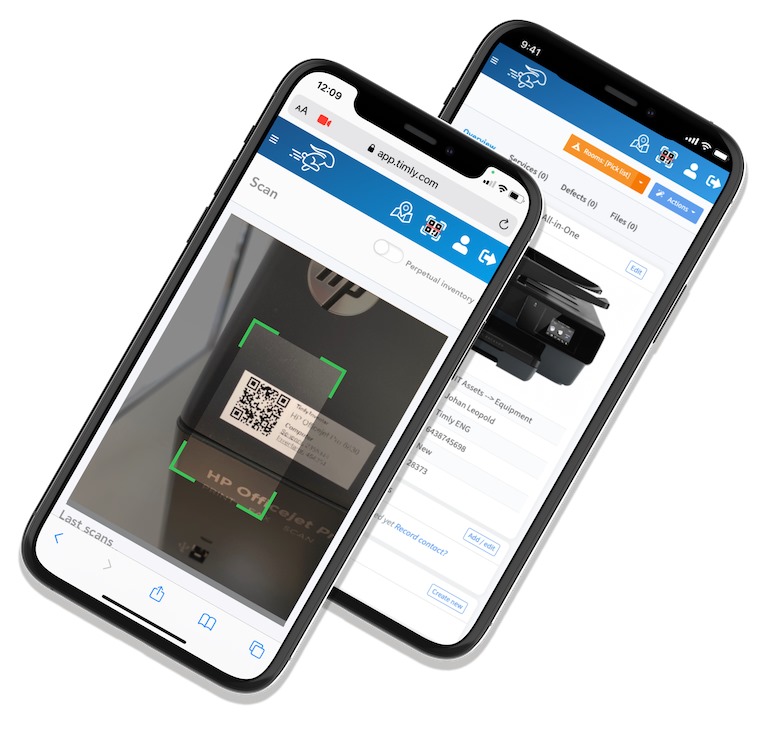

In this blog post, we explore the core aspects of automated maintenance management. We’ll uncover its many benefits and offer practical insights on how companies can leverage this technology to revolutionize their maintenance processes. Our focus will include a look at asset management systems like Timly, a Zurich-based leader in Asset Management Software, showcasing how they are redefining the way businesses approach maintenance tasks and processes.

Why Maintenance Management Matters

Let’s begin with the essence of maintenance management. Central to any successful business utilizing tools, equipment, furniture, machinery, or vehicles is a vital, continuous process: maintenance management. This goes beyond mere repair work – it’s a strategic endeavor aimed at ensuring your facilities, machinery, and other assets operate seamlessly. The objective is twofold: to avert failures and sidestep the unwelcome disruptions of unplanned downtime that can disrupt your operations. Equally important is the role of maintenance management in preventing workplace accidents and the subsequent repercussions they entail.

Reactive vs Preventive Maintenance

Maintenance management is divided into two primary strategies: reactive and preventive. Reactive maintenance acts as your emergency response team, springing into action when equipment breaks down. It’s about immediate problem-solving and repair in the face of unexpected issues.

Conversely, preventive maintenance serves as your proactive shield. This approach is centered around regular check-ups and timely repairs, aimed at identifying and resolving potential issues before they escalate into major problems.

The art of maintenance management lies in the effective understanding and balancing of these two strategies. By integrating both reactive and preventive approaches, businesses can ensure a smooth, uninterrupted flow of operations, maintaining the rhythm and reliability of their daily activities.

The Power of Automation in Maintenance Management: Streamlining and Strategic Focus

The adoption of automated maintenance management software, such as Timly, signifies a pivotal change for businesses. This innovative approach is laden with benefits that greatly enhance operational efficiency and productivity.

Key to this transformation is the streamlining of maintenance processes. Automation significantly reduces the time and effort that traditional methods demand, thereby accelerating operations. This not only speeds up routine tasks but also allows your team to divert their attention to more strategic, value-adding activities.

Additionally, automated systems emerge as powerful tools for data analysis. They offer insightful and actionable data, enabling smarter, data-driven decision-making. This capability to analyze and anticipate potential issues is crucial for proactive problem-solving and maintenance.

Enhancing Accountability, Cost Efficiency, and Reducing Downtime

Another major advantage of automated maintenance management is the increased level of accountability and transparency it introduces. With every operation and task being meticulously tracked and recorded, a clear and auditable trail is established. This transparency ensures that all team members are consistently informed and aligned, promoting a unified approach to maintenance tasks.

Cost savings also stand out as a significant benefit of automation. By minimizing manual errors and optimizing maintenance schedules, these systems effectively reduce unnecessary expenses, contributing positively to the financial health of the business.

Lastly, one of the most critical impacts of automation is its role in reducing downtime. Automated systems are adept at swiftly identifying and addressing issues, significantly cutting down on unexpected equipment failures and the expensive downtimes associated with them. This efficiency is key to maintaining steady, uninterrupted business operations.

Data-Driven Insights in Automated Maintenance Management

Automated maintenance management systems have evolved beyond their traditional roles, emerging as powerful data hubs that provide real-time insights into maintenance activities. This wealth of information is invaluable, serving as a goldmine for informed decision-making.

By leveraging this data, maintenance teams are empowered to allocate resources with greater efficiency and prioritize tasks with unprecedented precision. The ability to identify trends and patterns in maintenance needs marks a significant shift. Teams evolve from merely reacting to problems to proactively anticipating and addressing them, ensuring a more strategic approach to maintenance.

Strategic Advancement through Long-Term Data Analysis

The long-term data collection capabilities of automated maintenance management systems are a key component of their strategic value. Over time, the accumulated data becomes a rich resource for continuous improvement and strategic planning.

Businesses can analyze this historical maintenance data to uncover recurring issues, evaluate the effectiveness of their maintenance strategies, and refine their processes for enhanced results. This deep dive into data analysis transforms maintenance from a routine operational task into a strategic function. Such a transformation not only improves the efficiency of maintenance operations but also significantly contributes to the overall growth and development of the organization.

Embracing Technology: The Evolving Business Mindset

In maintenance management, the shift toward automation is more than just a series of technological upgrades – it represents a fundamental change in business mindset. Today, businesses are increasingly recognizing the pivotal role of maintenance in their operations. This transformation leads us to a crucial question: How can businesses harness technological tools to not only adapt but thrive in this evolving landscape?

As we journey through the different facets of maintenance management, from reactive and preventive strategies to the game-changing power of automation, it becomes evident that we stand at the threshold of a new era in business operations.

The integration of emerging technologies, such as AI and IoT, with automated maintenance systems is set to revolutionize the field further. Picture a future where predictive maintenance reaches new heights, with AI algorithms not only foreseeing potential failures but also recommending optimal maintenance schedules and procedures. Meanwhile, the IoT offers unparalleled connectivity, enabling real-time asset monitoring and management across multiple locations.

Looking Ahead: Maintenance Management in 2024 and Beyond

Furthermore, sustainability is emerging as a cornerstone of modern business operations. In this context, maintenance management assumes a pivotal role in ensuring eco-friendly practices. Automated systems are poised to optimize resource usage and reduce waste, aligning maintenance practices with the global push toward sustainability.

In conclusion, as we embrace the future of maintenance management, businesses must adopt an agile and innovative approach. The journey ahead entails not just adapting to changes but also leading the way in redefining how maintenance contributes to the success and sustainability of businesses. The question now is not if, but how swiftly businesses can align with this evolving landscape to unlock the full potential of automated maintenance management.